Properties/Characteristics: Motion Damper and Lid Stop Damper STAB-O-SHOC HD dampers from Tieying are the most cost-efficient type for safe and reliable damping of uncontrolled movements.

As standard motion and lid stop dampers, they are characterized by a simple design, which makes them easy and inexpensive to manufacture. Further advantages are their high quality and safety levels, outstanding performance, and long service life of each damper.

STAB-O-SHOC oil-hydraulic motion or lid stop dampers come in two basic types; damping force is laid out either in the direction of tension or compression. It is characterized by a damping force required in only one direction of motion. It can also be varied path-dependent via the stroke by means of bypass grooves.

As simple lid end stop and motion dampers they are designed for vertical, orientation-specific mounting. However, when equipped with an additional, closed separating element, they can also be installed regardless of orientation.

Therefore, they are ideal as vibration dampers.

For a function overview of our STAB-O-SHOC damper product line, please refer to the selection matrix.

Damper Product Variants

Typical Motion and Lid Stop Dampers

STAB-O-SHOC HD 15 – orientation-specific standard damper for low damping forces

STAB-O-SHOC GD 15 – orientation-specific standard damper for low damping forces with additional extension force

STAB-O-SHOC GD 15 SP – damper for low damping forces with positive force transmission in both directions of motion, non-specific mounting orientation, and additional extension force

STAB-O-SHOC HD 24/29 – orientation-specific standard damper for high damping forces

STAB-O-SHOC GD 24/29 – orientation-specific damper with separating piston for high damping forces in tension and compression direction with additional extension force

STAB-O-SHOC GD 24/29 SP – damper with separating piston, for higher damping forces with positive force transmission in both directions of movement, additional extension force, and non-specific mounting orientation.

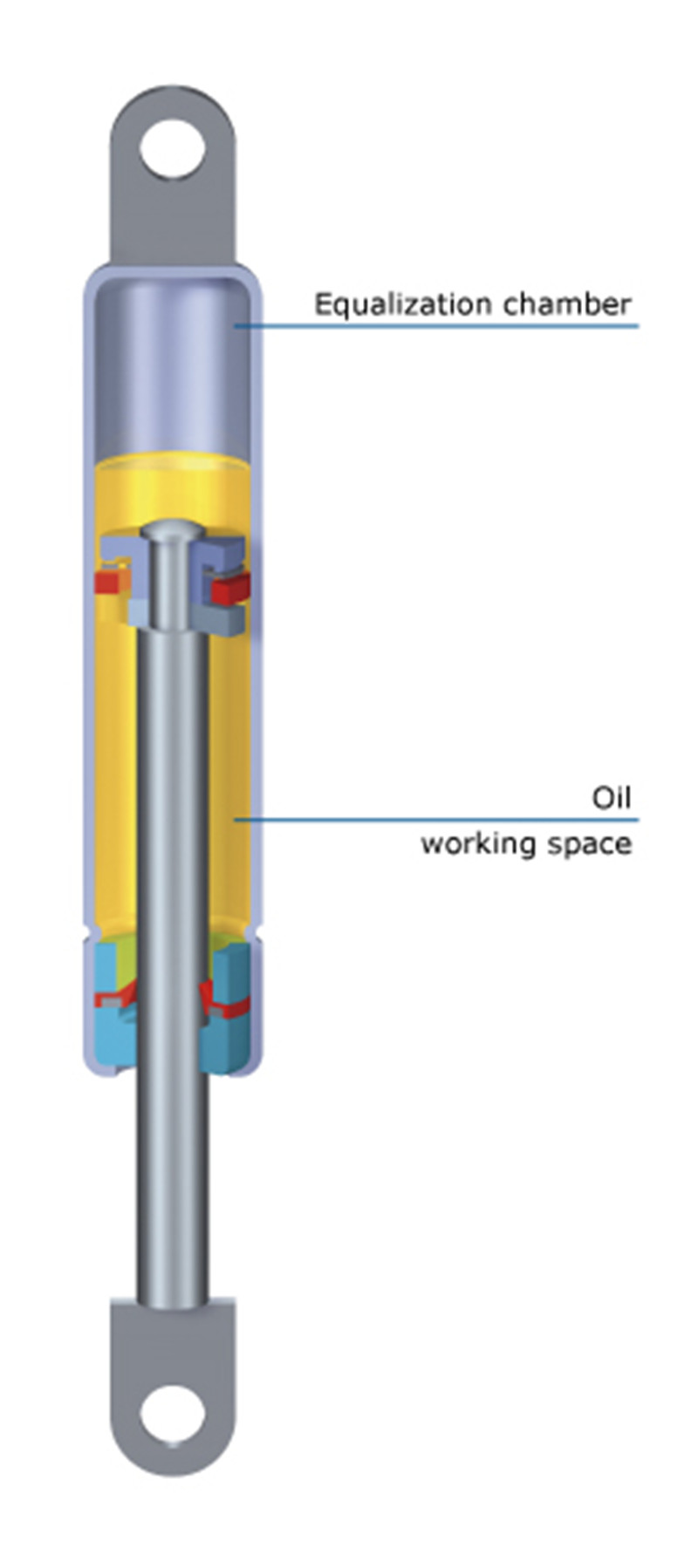

STAB-O-SHOC HD 15

Even small and light-weight lids and armatures can present risks.

Especially if they open by themselves or if their fall is not braked. In the worst case, fingers will get squeezed.

To prevent this from happening, there is now the STAB-O-SHOC HD 15 from Stabilus. It gently dampens the motion, and due to its small, simple design it can easily be integrated into any application.

Function

The standard STAB-O-SHOC is a mounting orientation-dependent, non-pressurized oil hydraulic damper, which is preferably installed vertically. Positive and direct force transmission is possible in only one direction of motion.

Advantages

Damping force up to 800 N

Damping forces one-directional, in special cases also bi-directional

Non-pressurized, no extension force

Orientation-dependent mounting, with piston rod down or up

“Plunger damper” – simple design

Applications

Glove compartment

Bar cabinets

Kitchen cabinets

Storage cubicles

Lid dampers

STAB-O-SHOC GD15

The STAB-O-SHOC GD 15 is used whenever light force assist is desired in addition to gentle damping.

Function

In this proven damper from Stabilus, the interior is under higher pressure than in the standard STAB-O-SHOC. The resulting extension force will extend the piston rod automatically. In the compression direction, the damping force will increase by the amount of the extension force.

Advantages

Damping force max. 800 N

Damping forces one-directional, in special cases also bi-directional

With extension force

Orientation-dependent mounting, with piston rod down or up

Applications

End position damper

Light flaps

Soft top damper, e.g., convertible top

Foot-operated parking brakes

End position damper

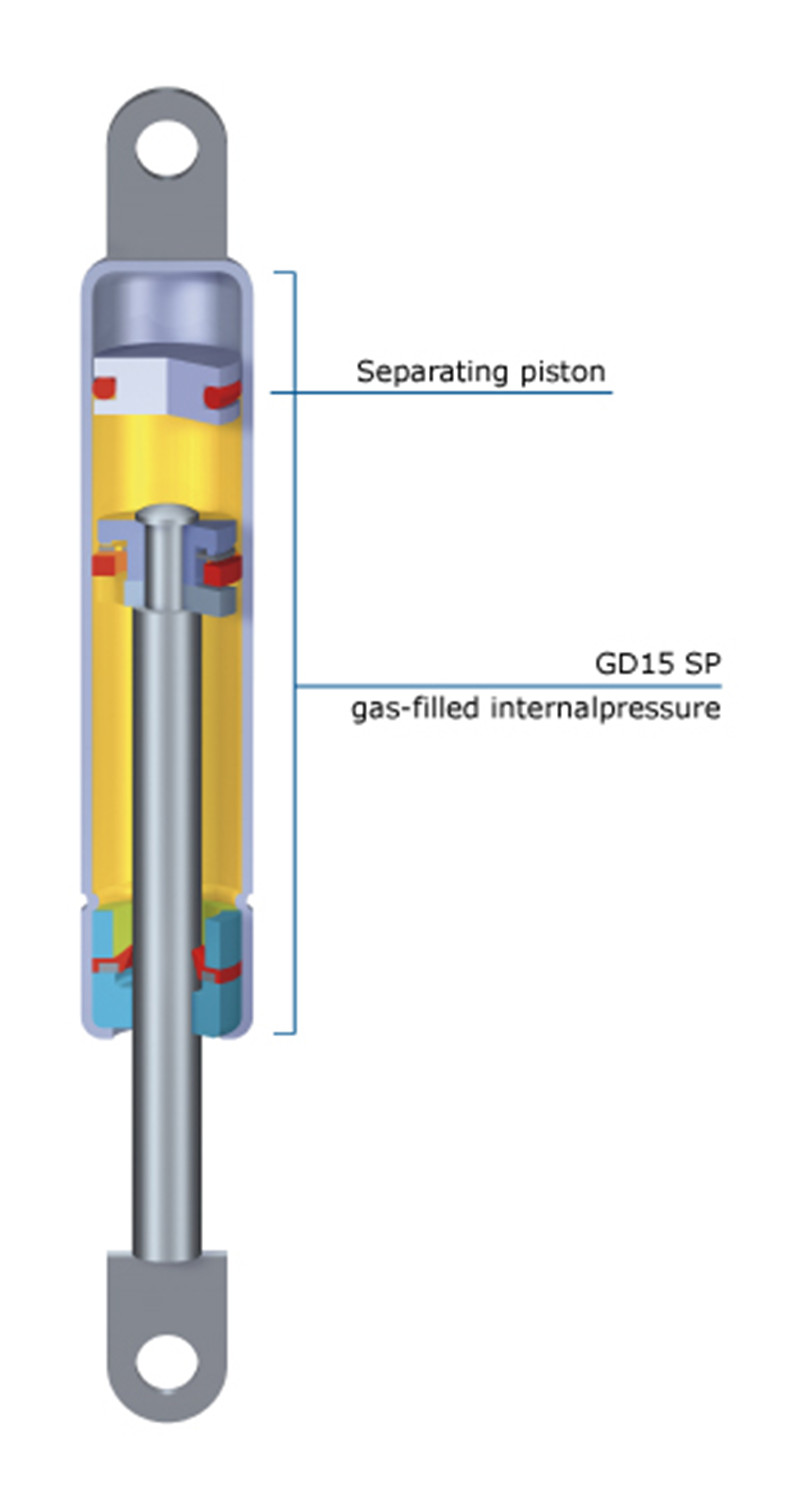

STAB-O-SHOC GD15 SP

Furniture designers like to let their ideas run free. That requires dampers that can be installed in any position.

Function

Like the GD 15, the STAB-O-SHOC GD 15 SP is under higher internal pressure, which provides additional extension force. In addition, a separating element separates the working chamber from the equalization chamber, enabling positive, direct force transmission in both directions of motion.

Advantages

Damping force max. 800 N

Damping forces one- or bi-directional

With extension force

Positive, direct instant damping

Non-specific mounting orientation

Piston rod installation in any direction

Applications

Consoles

Light flaps

Furniture fittings